Many variables influence the type of pipeline used in the oil and gas business, including the ‘product’ to be delivered, the delivery stage, and whether it is in the upstream, midstream, or downstream sector. If you’re a seasoned hot tapping engineer, you’ll already be familiar with these. However, for the rest of you, basic definitions of the main types of pipelines and their overall function are provided below.

- Pipeline Varieties

2. Pipelines are being collected.

3. Pipelines for Transmission and Distribution

4. Pipelines for Flowlines and Feeders

- PIPELINE GATHERING TYPES

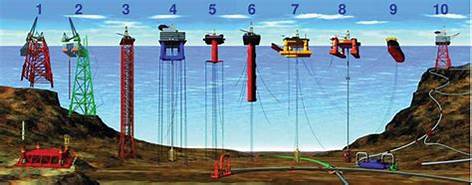

What do they serve? – Gathering pipelines transport oil or gas from the source to processing units or storage tanks. These are frequently supplied by ‘Flowlines,’, each of which is linked to a separate well in the earth. This category also includes subsea pipelines used to collect goods from deep ocean production sites.

Gathering pipelines typically transport natural gas, crude oil (or mixtures of these two products), and natural gas liquids such as ethane, butane, and propane. The raw gas is often transported in collection pipelines at pressures of around 715 psi.

What are the dimensions of collecting pipelines? – In comparison to other pipelines, the lengths in this category are quite modest – around 200 meters. They are normally considerably smaller than transmission pipes, with diameters of less than 18″ (although for crude oil, often 2 – 8″), however recent improvements in shale production have seen collection lines with diameters as big as 20″.Is the regulation of gathering pipes in place? – Gathering pipelines are regulated in moderate to moderately populated regions in the United States, but less so in ‘rural’ areas. As newly constructed neighborhoods expand, they frequently encroach on these regions, posing significant safety concerns. As a result, the PHMSA (Pipeline & Hazardous Materials Safety Administration) modified the standards in 2006 to include gas collection pipes in ‘rural’ regions within 14 miles of a ‘USA’ (unusually sensitive area). A USA is defined as an area that includes a drinking water source or an ecological resource region that is exceptionally vulnerable to environmental damage caused by a hazardous liquid pipeline discharge.

- PIPELINE TRANSMISSION TYPES

What do they serve? – Transmission pipelines convey crude oil, NGLs, natural gas, and refined products. for lengthy journeys across states, regions, and continents

Transmission pipes are used to transport products from manufacturing areas to distribution centers. They run at high pressures ranging from 200 to 1,200 psi, with each transmission line employing compressor stations (for gas lines) and pump stations (for crude oil and liquid products).

What is the reason for transmission line failure? – Common causes of transmission line failure include pipe seam failures, corrosion, material failure, and poor welding.

What size are transmission pipelines? – These enormous pipes can have a diameter of up to 42 inches, with the majority having a diameter of more than 10 inches.

- PIPELINE DISTRIBUTION TYPES

What do they serve? – Distribution pipelines are a system utilized by distribution corporations that is made up of’mains’ and’service’ lines. They work together to bring natural gas to residential and commercial areas.

Mains pipelines – The’mains’ distribution pipes are the link between high-pressure transmission lines and low-pressure service lines. Steel, cast iron, plastic, and copper are among the materials utilized to make these pipes. Pressures can vary greatly and might reach up to 200 psi.

Service pipes link to a meter and distribute natural gas to individual consumers. Plastic, steel, and copper are all common materials for service pipes. The gas pressure in these pipelines is modest, about 6 psi.

What are the dimensions of distribution gas pipelines? – ‘Mains’ distribution pipes are modest to medium in size (diameters ranging from 2″ to 24″). Pipelines used for service are typically narrow (less than 2″ in diameter).

- LINES OF FLOW, FLOWLINES

In an oilfield that is actively producing, flowlines are linked to a single wellhead. Their mission is to transport raw material from the wellhead to the collecting lines. They transport a combination of oil, gas, water, and sand and are typically little more than 12″ in diameter.

The significance of flowline upkeep – Flowlines are prone to methane leakage, and the EPA (Environmental Protection Agency) in the United States reports that they are one of the main sources of emissions in the gas business. To decrease gas losses, the EPA recommends monitoring flowlines once a year. Regular maintenance helps to keep tiny leaks from becoming larger over time.

- FEEDER PIPELINES Feeder pipelines transport products from processing plants and storage tanks to long-distance transmission pipelines. It might be crude oil, natural gas, or natural gas liquids. Feeder lines generally range in diameter from 6 to 12 inches.

What on-site machines are available for pipeline building and maintenance? – The portable machine tools indicated below can be used for a variety of tasks including resurfacing sealing surfaces on damaged flanges, cutting and bevelling (for flange welding preparation), and tapping into a live line to add extra sections.